Ceramic Capacitor

A ceramic capacitor is an electronic component used to store and release electrical energy. It consists of a ceramic material sandwiched between two metal plates, acting as a dielectric. Ceramic capacitors are commonly used for filtering noise, decoupling, and stabilizing voltage in electronic circuits.

Type of Ceramic Capacitor

There are several types of ceramic capacitors, including:

1. Multilayer Ceramic Capacitors (MLCC): These are the most common type and are available in a wide range of capacitance values and voltage ratings.

2. Ceramic Disc Capacitors: These have a ceramic disc shape with leads attached to them, often used for high-voltage applications.

3. Ceramic Chip Capacitors: Surface mount versions of MLCC, designed for compact PCB layouts.

4. High-Q Ceramic Capacitors: These capacitors are optimized for high-quality factor (Q-factor) applications, such as in RF circuits.

5. Class 1 Ceramic Capacitors: These capacitors have low capacitance tolerance and low losses, making them suitable for precise applications like timing circuits.

6. Class 2 Ceramic Capacitors: These capacitors have higher capacitance values and are commonly used for decoupling and bypassing applications.

Characteristics of Ceramic Capacitors

Ceramic capacitors have several key characteristics, including:

1. Capacitance: Ceramic capacitors are available in a wide range of capacitance values, from picofarads (pF) to microfarads (µF), allowing for various applications.

2. Voltage Rating: Ceramic capacitors have specific voltage ratings that indicate the maximum voltage they can handle without breakdown. It’s important to select a capacitor with a voltage rating higher than the maximum voltage in the circuit.

3. Temperature Coefficient: Ceramic capacitors exhibit a change in capacitance with temperature. The temperature coefficient specifies how much the capacitance value changes over a given temperature range.

4. Tolerance: Capacitors have a tolerance rating that indicates the acceptable deviation from the labeled capacitance value. Typical tolerances for ceramic capacitors range from ±5% to ±20%.

5. Frequency Response: Ceramic capacitors are known for their low Equivalent Series Resistance (ESR) and Equivalent Series Inductance (ESL), making them suitable for high-frequency applications.

6. Dielectric Type: Ceramic capacitors utilize a ceramic material as the dielectric. Different ceramic formulations result in varying performance characteristics, such as Class 1 ceramics with high stability and low losses, and Class 2 ceramics with higher capacitance values but less stability.

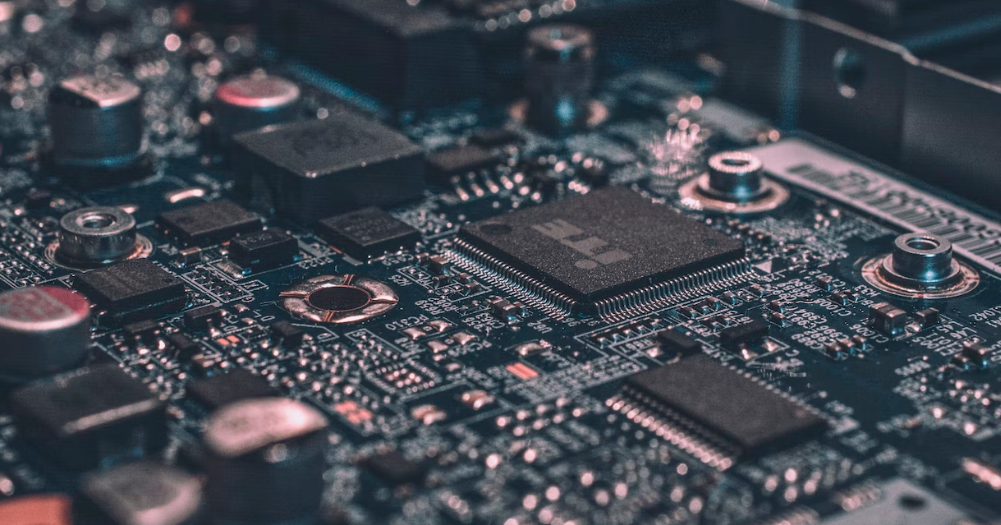

7. Size and Package: Ceramic capacitors come in various package sizes, including surface mount (SMD) and through-hole configurations, allowing for different mounting options on printed circuit boards.

8. Non-Polarized: Ceramic capacitors are non-polarized, meaning they can be connected in any direction in a circuit, unlike electrolytic capacitors which have specific polarity.

Applications and Uses of Ceramic Capacitor

Ceramic capacitors find applications in various electronic circuits and systems due to their desirable characteristics. Here are some common applications and uses of ceramic capacitors:

1. Decoupling and Bypassing: Ceramic capacitors are widely used for decoupling and bypassing purposes in electronic circuits to filter out noise and stabilize voltage levels, ensuring proper functioning of integrated circuits and preventing signal interference.

2. Timing and Oscillator Circuits: Ceramic capacitors are used in timing circuits and oscillator circuits to control the frequency and stability of signals, ensuring accurate timekeeping and synchronization.

3. Power Supply Filtering: Ceramic capacitors are employed in power supply circuits to filter out high-frequency noise and ripples, providing a cleaner and more stable power source for sensitive electronic components.

4. Coupling and Blocking: Ceramic capacitors are used for coupling signals between different stages of amplifiers and other circuits, allowing the AC component of the signal to pass while blocking the DC component.

5. RF and Microwave Applications: Due to their low equivalent series resistance (ESR) and equivalent series inductance (ESL), ceramic capacitors are suitable for use in RF and microwave circuits, such as filters, resonators, and matching networks.

6. Sensor Applications: Ceramic capacitors can be used in sensor applications, such as in capacitive touch sensors, where they provide the necessary capacitance for sensing changes in capacitance due to human touch or proximity.

7. Snubber Circuits: Ceramic capacitors are employed in snubber circuits to protect semiconductor devices from voltage spikes and transient surges, improving overall system reliability.

8. LED Lighting: Ceramic capacitors are used in LED lighting applications to provide power factor correction (PFC) and reduce harmonic distortion, ensuring efficient and reliable operation of LED drivers.

These are just a few examples of the many applications and uses of ceramic capacitors. The specific application and choice of capacitor depend on factors such as capacitance value, voltage rating, temperature requirements, and frequency response required for the particular circuit or system.